Loading... Please wait...

Loading... Please wait...Call us today 1-253-988-2046

Pure Timber LLC

Need to Know More? Have Feedback? Send us your comments here...

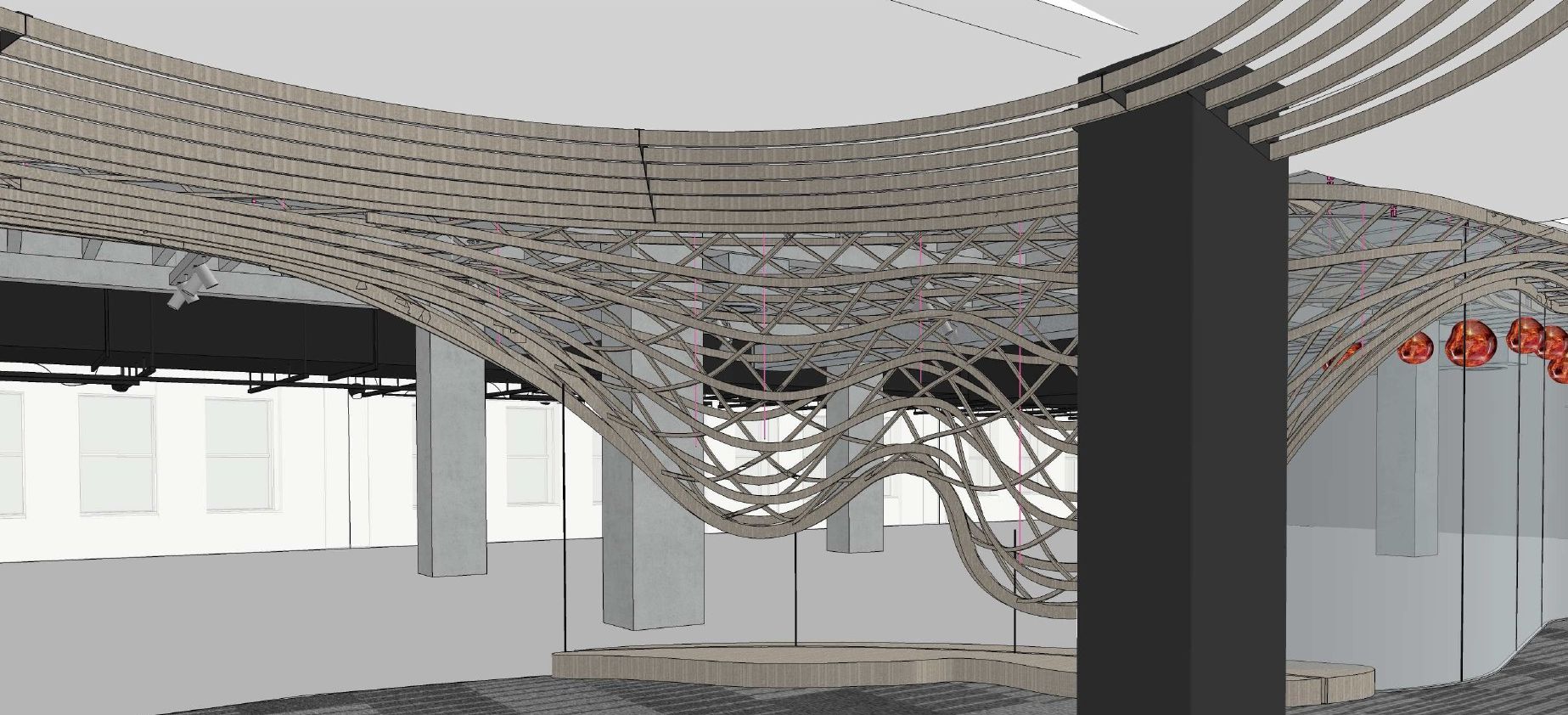

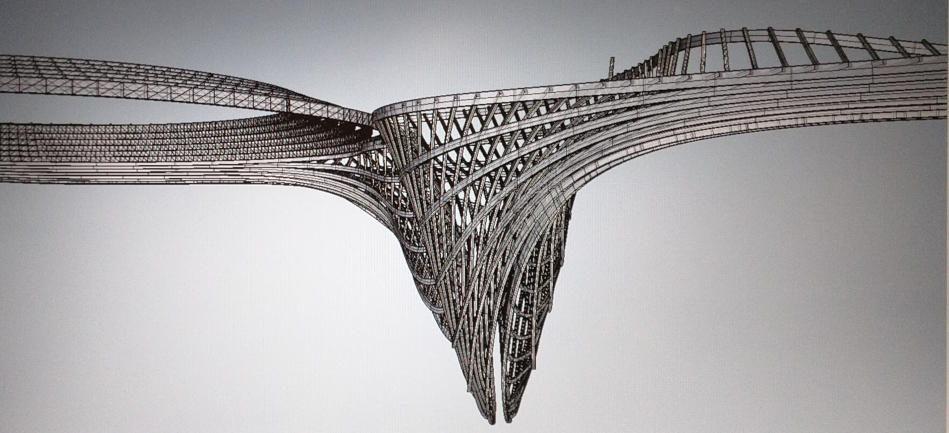

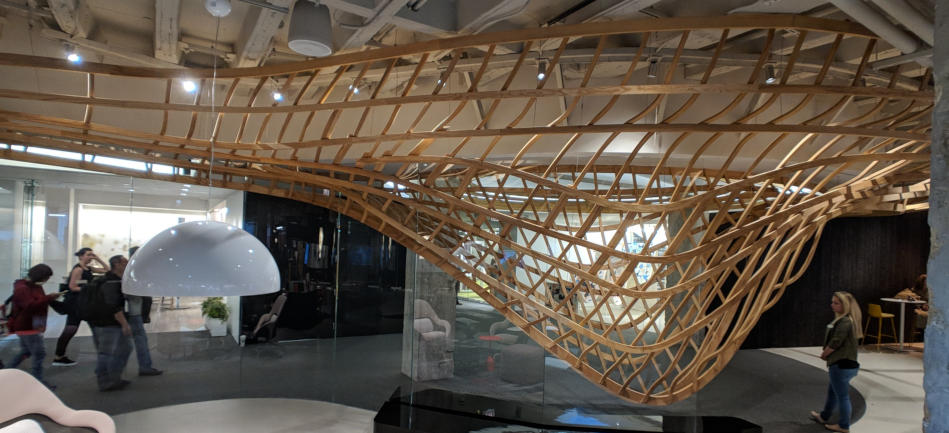

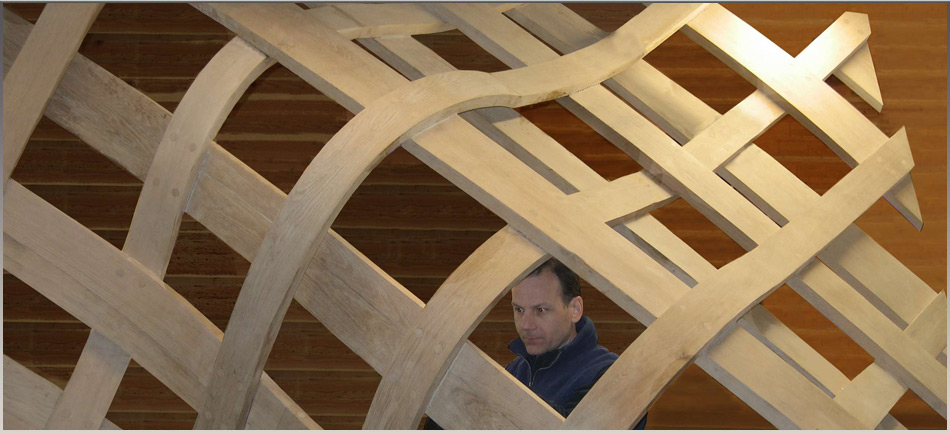

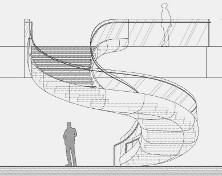

contact us today!Pure Timber produces bendable hardwood and bentwood products

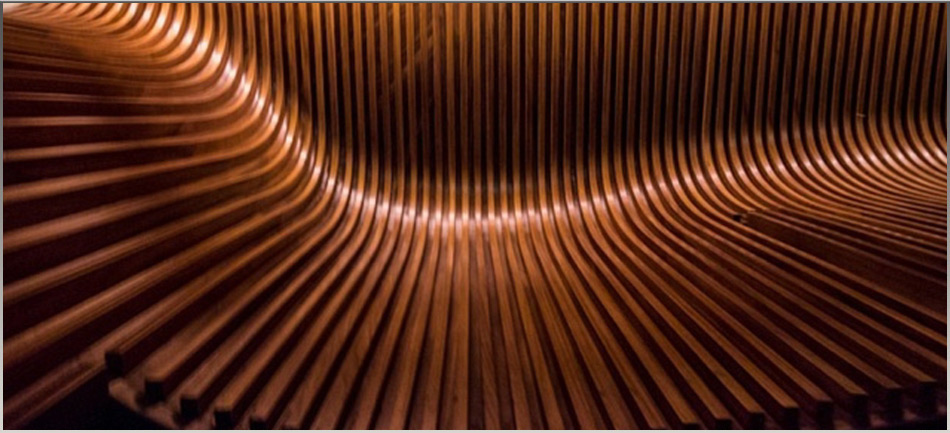

and fabrications using their proprietary Superwood Extreme Wood Bending™ process that produces the world's most dramatic and ambitious bentwood parts from thick, solid hardwoods.

If this is your first visit to the Pure Timber website, be prepared to experience a paradigm shift in wood bending...

What is it? Cold-Bend™ hardwood is a Superwood that is engineered, solid, cold-bendable hardwoods, that are uniquely suited to the most demanding Extreme Wood Bending™ projects. It is indistinguishable from clear, straight grained hardwood because that's what it is. It has just been subjected to carefully controlled, but intense, longitudinal thermo-mechanical compression. This Superwood has been engineered to be extremely flexible (as long as it is moist). Once cold-bent by hand (or with jigs, clamps and fixtures), Cold-Bend™ hardwood is dried to fix the shape.

Why does it work? This Superwood works because it can stretch. When wood bends, it has to stretch on the outside of the curve, which gets longer. Wood can't stretch, so steam benders use a steel backing strap on the outside of the curve to force compression to the inside of the bend (the inside gets shorter, but the outside stays the same length). With Cold-Bend™ Hardwood, the wood is compressed before it is bent, making it a "Superwood". Therefore it can stretch on the outside of the curve during bending - no steam or backing strap needed. Since the wood is first plasticized in an autoclave and then compressed in a hydraulic press, very tight radii can be bent. We can bend this Superwood in any direction, make S-curves, twist it, and bend it on edge.